microencapsulation companies

Microencapsulated Products are special products formed by encapsulating core substances within tiny capsule walls using microencapsulation technology, with diameters typically ranging from micrometers to millimeters. This exquisite design at the micro level provides multiple protections and functional extensions for the core material, making it an innovative product form that spans multiple fields. The structure of Microencapsulated Products embodies the wisdom of micro design Micro encapsulated consists of two parts: core material and capsule wall material. The core material can be solid, liquid, or gas, such as bioactive ingredients, functional oils, fragrances, etc; The material of the capsule wall is selected according to the application requirements, commonly including natural polymer materials (such as gelatin, sodium alginate), synthetic polymer materials (such as polyamide, polyethylene glycol), and inorganic materials (such as silica). The capsule wall is formed by interfacial polymerization, spray drying and other processes, which can not only tightly wrap the core material, but also control the release according to the external conditions to build a "protective barrier" for the core material. The complex characteristics of Microencapsulated Products give them unique advantages in various fields The delayed release characteristic is one of the core functions of microencapsulation . The capsule wall can accurately control the release speed and time of core substances based on external stimuli such as temperature, pH value, and pressure, for example, achieving drug sustained release effect in the pharmaceutical field. In terms of stability, the capsule wall can isolate oxygen, moisture, and light, protect the core material from external environmental influences, and extend the shelf life of the product. The thermal protection properties allow thermosensitive core substances to remain active during high-temperature processing, such as probiotic microcapsules in food processing. In addition, it can improve the sensory characteristics of core substances, mask unpleasant odors or tastes, and have good environmental adaptability, which can exist stably under different temperature and humidity conditions. Microencapsulated Products have a wide and in-depth range of application scenarios In the food industry, spray drying in microencapsulation can be used for the retention and release of flavor compounds, allowing food to maintain a rich flavor during storage and consumption; In the field of cosmetics, microcapsules containing active ingredients can enhance the penetration effect of skincare products and reduce irritation; In the field of agriculture, microencapsulated pesticides can achieve slow release, improve utilization efficiency, and reduce environmental pollution; The pharmaceutical industry uses it as a drug carrier to achieve targeted drug delivery and long-term treatment. With the advancement of materials science and process technology, the performance of Microencapsulated Products continues to be optimized The development of new capsule wall materials has improved packaging efficiency and control accuracy, and more advanced preparation processes have reduced production costs, enabling them to achieve large-scale applications in more fields. In the future, customized microcapsule products for specific scenarios will become a development trend, further expanding their application boundaries. In summary, food microencapsulation , with its unique structural design, integrates complex characteristics such as delayed release, stability, thermal protection, sensory optimization, and environmental adaptability, playing an irreplaceable role in multiple fields such as food, medicine, and cosmetics. It not only reflects the precise control of material properties by micro technology, but also provides new ideas for innovative development in various industries, demonstrating broad application prospects and profound technological value. Microencapsulated Products FAQs What is the delayed release feature of Microencapsulated Products? The delayed release characteristics of Microencapsulated Products refer to the gradual release of active ingredients by encapsulating them in microcapsules through special processes under specific conditions such as time, temperature, or pH changes. This technology can prolong the action time of ingredients, avoid waste or effect overload caused by one-time release, and is widely used in the fields of medicine, food additives, and agriculture, achieving the goal of precise control of release rate. How can Microencapsulated Products improve product stability? Microencapsulation isolates external factors such as oxygen, moisture, or light through physical barriers, effectively protecting core components such as vitamins, probiotics, or essential oils from degradation. For example, easily oxidizable fish oil has a significantly extended shelf life after microencapsulation. In addition, the selection of capsule wall materials (such as gelatin and polysaccharides) can further optimize the chemical stability of ingredients in different environments, ensuring that the product remains active during storage or transportation. Why does Microencapsulated Products technology provide thermal protection? Microencapsulation technology wraps heat sensitive components (such as enzyme preparations or fragrances) around high-temperature resistant wall materials (such as modified starch, polymers) to prevent them from being damaged during high-temperature processing (such as baking, sterilization). The capsule wall remains intact at room temperature and only melts or ruptures when reaching the target temperature or triggering conditions, thereby protecting the efficacy of the core components. It is suitable for products that require heat treatment but need to retain activity. How do Microencapsulated Products improve the sensory characteristics of their products? Microencapsulation can mask the off flavors of certain ingredients (such as bitterness and fishy taste), or reduce the impact on taste by controlling release. For example, in functional foods, the metallic taste of iron is encapsulated and only released during digestion, enhancing the eating experience. In addition, the particle size and texture of the capsules can be adjusted to avoid graininess, making the product smoother and meeting consumers' dual needs for flavor and taste. How do Microencapsulated Products adapt to different environmental conditions? Microencapsulated Products can activate release in specific environments by designing responsive wall materials such as pH sensitive and temperature sensitive. For example, pesticide microcapsules degrade slowly in soil, reducing rainwater erosion and loss; Probiotic capsules are released in the pH environment of the intestine, avoiding damage from stomach acid. This adaptability significantly enhances the effectiveness and reliability of the product in complex environments.

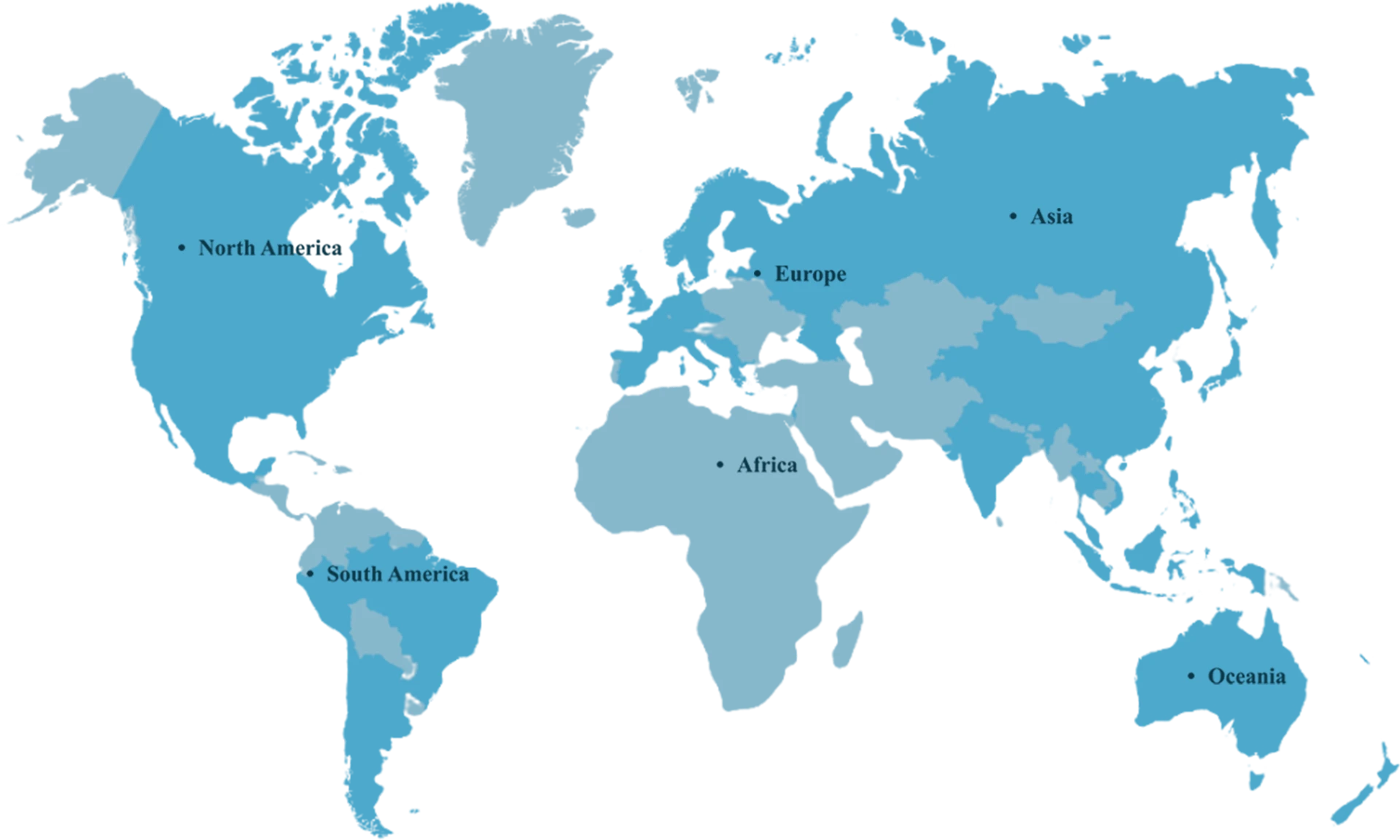

Finutra devotes to be an integrated supplier for global supply chain, we offer a

broad array of raw materials and functional ingredients

Authoritative Certification

Continuous Innovation, Customer First

Enhance core competitiveness to bring customers better products and services,

Each of these is the result of our team's relentless pursuit of excellence

and our deep commitment to social responsibility.

Global

Reach

FINUTRA has over 350,000 square feet of manufacturing and warehouse

space worldwide.

Industries We Serve

Advanced molecular distillation and microencapsulation

technology. Extremely bioavailable

trace carotenoids Intuitively soluble.

STAY UPDATED

Receive special offers and first look at new

products.

products.

Building 23B1, No.2 Yuanboyuan St., Zhengding Area of China (Hebei) Pilot Free Trade Zone

QUICK LINK

Finutra devotes to be an integrated supplier for global supply chain, we offer a broad array of raw

materials and functional ingredients as a manufacturer, distributor and supplier for global Beverage,

Nutraceutical, Food, Feed and Cosmeceutical.

Copyright © 2025 Hebei Finutra

Biotech Co.,

Ltd. All

Rights Reserved.

Privacy Policy

![Alpha GPC-Hebei Finutra Biotech|[Cognitive Enhancement]&[Athletic Performance] Alpha GPC-Hebei Finutra Biotech|[Cognitive Enhancement]&[Athletic Performance]](https://www.finutra.com/images/7_6-webp1731551991.webp)